Welding

Precision Welding, For Diverse Applications.

Diverse welding techniques, certified to meet safety and quality codes, allow us to work with many different materials, sizes, and quantities, including weldments up to 60’ long and weighing 40 tons.

Multiple welding stations allow for more efficient set-up and throughput. Our certified, experienced welders can handle a range of materials including aluminum, stainless steel, and mild steel.

The cutting-edge laser welding capabilities of our LightWELD XR include 4 times faster welding than TIG and the ability to weld dissimilar materials.

Equipment:

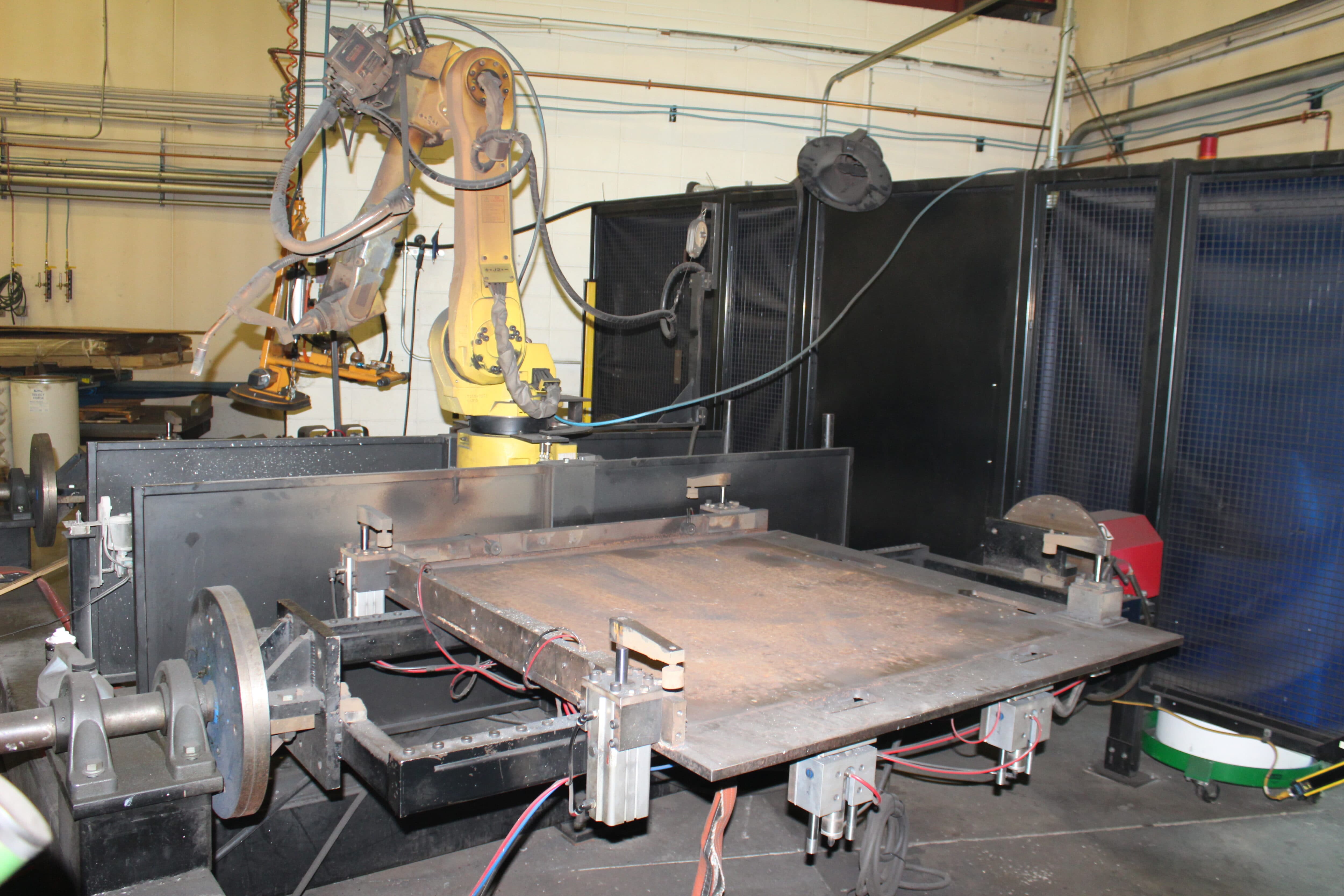

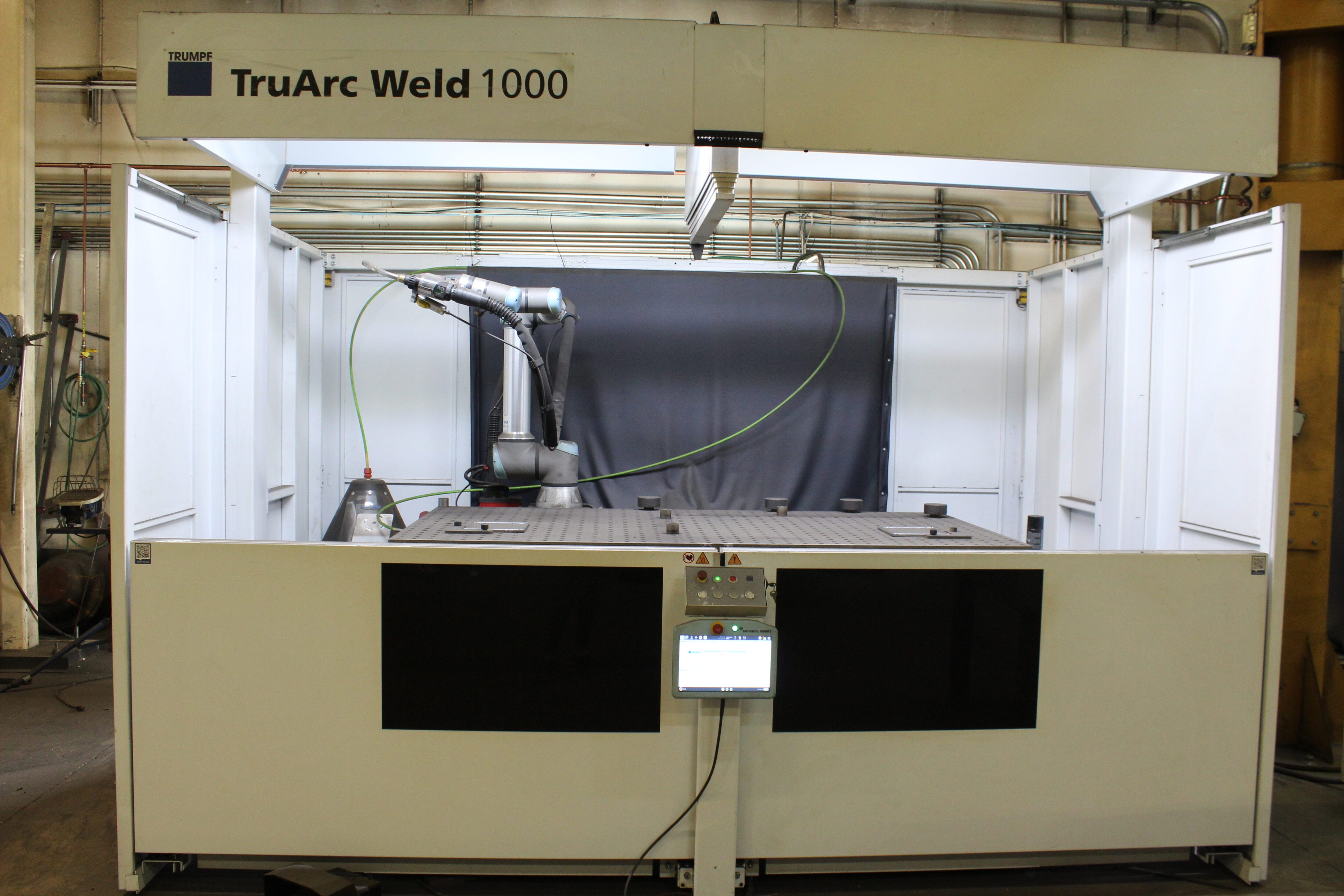

- (2) Robotic Welding Cells, 48” x 80”

- Multiple MIG, TIG and SMAW stations

- Handheld LightWELD XR

Certified: AWS/ANSI D1.1, D1.2, D1.6, ASME